Overview

- Ultimate Performance

- Premium Comfort

- Faster connectivity

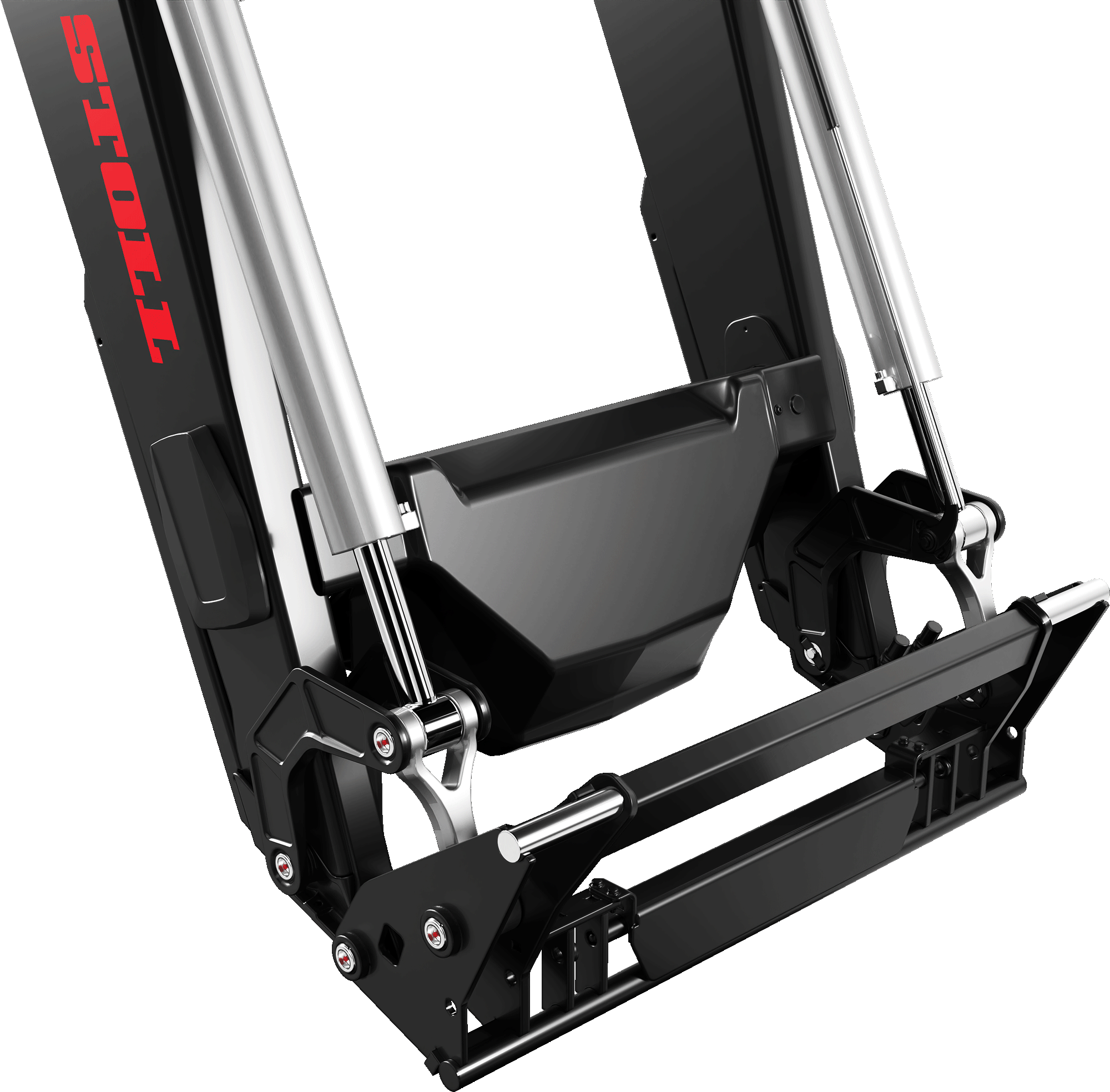

The new STOLL ProfiLine ISOBUSConnected brings the full integration of the front loader into the tractor system. The new system settings, new level of comfort and higher safety standards.

The ISOBUS standard unifies the communication between the tractor and the new Stoll's front loader. Thanks to it ISOBUSConnected front loader can be fully integrated into the tractor.

With the STOLL ProfiLine ISOBUSConnected, the front loader can be connected to the tractor control unit and operated by the tractor joystick and terminal.

In addition to the electro-hydraulic parallel levelling on the FS model, the new STOLL ProfiLine ISOBUSConnected system also offers professional functions that turn the tractor with the Stoll front loader into a true professional machine.

The unique STOLL ProfiLine ISOBUSConnected features take front loader and tractor work to a new level of comfort, user-friendliness and precision.

functions.

2025 STOLL

2025 STOLL